When it comes to maintaining your vehicle, horn attachments might not be the first thing you think about. However, a malfunctioning horn can be a real inconvenience, whether it’s not sounding loud enough, not working at all, or producing a strange noise. In this guide, we’ll walk you through some common issues with horn attachments and how you can fix them yourself.

What Are Horn Attachments and Why Do They Matter?

Before diving into troubleshooting, let’s first understand what horn attachments are. A horn attachment is a crucial component that connects the horn to your vehicle’s electrical system. This connection ensures that when you press the button on your steering wheel, an electrical signal is sent to the horn, making it sound. Without this proper connection, your horn simply won’t work, which can create significant safety issues, especially in situations where you need to alert other drivers or pedestrians.

Horn attachments come in various forms, typically including wires, fuses, and switches that all work together to deliver the signal to the horn itself. These components are responsible for the electrical activation of the horn, meaning if one part fails, the entire system could stop working. Issues can arise when any of these attachments become faulty, which could range from minor problems like a loose wire to more severe issues such as a burnt fuse or damaged switch.

When the horn attachment is not functioning properly, you might not notice it immediately, but it can leave you in vulnerable situations. For instance, imagine trying to signal a dangerous driver or avoid an accident, but your horn doesn’t respond. This could be extremely dangerous, as horns are often used to prevent accidents or warn other drivers of your presence. A malfunctioning horn can also create frustration for other drivers who may not be aware of your intentions on the road.

Therefore, it’s important to pay attention to any signs that your horn attachment might be having trouble. Whether it’s a faint sound, no sound at all, or a strange noise, these signs are signals that something isn’t quite right. Recognizing these issues early on and addressing them can prevent further damage, save time and money, and ultimately keep your vehicle safe and functional.

Common Horn Attachment Problems

| Issue | Cause | Symptoms | Diagnosis | Solution |

| Horn Not Sounding at All | Blown Fuse | No sound when horn button is pressed | Check fuse box for burnt or broken fuse | Replace the blown fuse |

| Loose Wiring or Connections | Horn doesn’t respond or is intermittent | Inspect wires for damage, fraying, or loose connections | Repair or replace damaged wiring or connectors | |

| Faulty Horn Switch | No response when pressing the horn button | Test the switch using a multimeter to ensure it’s activating the horn | Replace the faulty switch | |

| Broken Horn | Horn produces no sound at all or strange noises | Directly connect the horn to a battery to test if it produces sound | Replace the broken horn | |

| Horn Making Strange Noises | Corrosion or Rust | Distorted or faint honking sound | Inspect the horn attachment for visible signs of rust or corrosion | Clean the rust or replace corroded parts |

| Dirty Horn Mechanism | Faint or distorted sound, honk sounds muffled | Check the horn mechanism for dirt or grime buildup | Clean the horn with compressed air or a cleaning solution | |

| Loose Horn Attachment | Rattling or vibrating sounds when pressing the horn button | Check for loose horn attachment or mounting bolts | Tighten the attachment or secure the horn in place | |

| Weak or Faint Horn Sound | Low Voltage | Weak or faint sound when horn is pressed | Check the battery voltage to ensure it’s fully charged | Charge or replace the battery |

| Weak Fuse | Sound is weaker than usual, horn doesn’t reach full volume | Inspect fuse for partial damage or breakage | Replace the fuse with a correct amperage rating | |

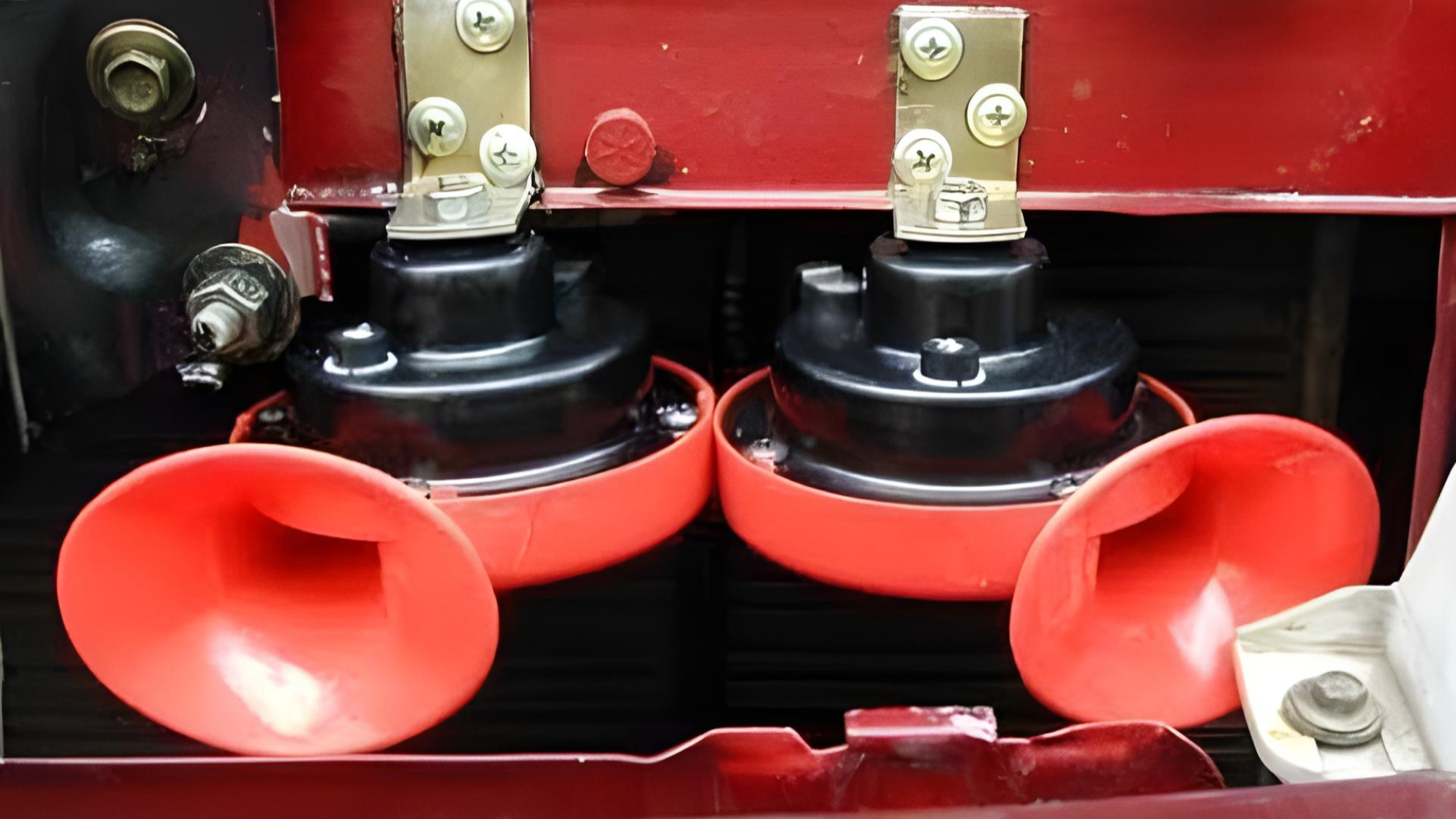

| Clogged Air Ducts (for air-powered horns) | Faint or weak sound, sound volume low | Check air passages for blockages or restrictions | Clear the ducts or replace the air-powered horn |

How to Troubleshoot Horn Attachments

- Check the Fuse

If the horn isn’t sounding at all, a blown fuse is often the culprit. Here’s how to check it:- Locate the Fuse Box: Your vehicle’s manual will indicate where the fuse box is located. It’s typically under the dashboard or in the engine compartment.

- Find the Horn Fuse: Inside the fuse box, look for the horn fuse. It will be labeled clearly.

- Inspect the Fuse: If the fuse is broken or burnt, it needs to be replaced. A replacement fuse can usually be found at any auto parts store.

- Inspect the Wiring

Loose or disconnected wires can prevent the horn from functioning. Here’s how you can check the wiring:- Turn Off the Vehicle: Ensure the vehicle is off before you start inspecting.

- Check for Visible Damage: Look at the wires connecting the horn to the battery and switch. If any wires are cut, frayed, or loose, they need to be repaired or replaced.

- Test the Connections: Use a multimeter to check the voltage at the horn connection. If there is no voltage, you may need to repair the circuit.

- Test the Horn Switch

The switch you press on the steering wheel may wear out or become faulty over time. Testing the horn switch is simple:- Locate the Switch: It’s usually located in the steering wheel assembly.

- Press the Button: While pressing the horn button, check if the switch is making contact. If it feels loose or doesn’t activate the horn, the switch may need to be replaced.

- Examine the Horn Itself

If the wiring and fuse are intact, the issue may lie with the horn itself. Here’s how to check it:- Remove the Horn: The horn is typically mounted in the front of the vehicle, near the grille. Use a wrench to remove it.

- Inspect for Damage: Check if the horn is physically damaged or clogged with dirt. A dirty horn can often be cleaned with compressed air or a cleaning solution.

- Test the Horn: You can test the horn by directly connecting it to a battery. If it doesn’t work, the horn is likely broken and needs to be replaced.

Fixing Common Horn Attachment Issues

Now that you’ve identified the issue, it’s time to fix it. The first step is often replacing the fuse. A blown fuse is a common culprit, and replacing it can resolve a lot of problems. To do so, make sure to get the right fuse with the correct amperage rating. This is essential to avoid further issues and ensure the horn works properly. Once you have the correct fuse, simply remove the broken fuse and install the new one. After installation, test the horn to ensure it works.

Next, you might have found some loose or damaged wires. Wires that are frayed, disconnected, or damaged can easily cause horn problems. To fix this, use wire cutters to remove the damaged section of the wire. After that, use a wire stripper to expose the bare wire and twist the wires together. If you want a stronger connection, you can solder the wires instead of using electrical tape. Be sure to secure the wires to prevent any future issues.

If the issue lies with the horn switch itself, it may need to be replaced. This process involves removing the plastic cover around the steering wheel to access the switch. Once exposed, disconnect the old switch and replace it with a new one. Ensure that the new switch is properly connected to the wiring, and reassemble the steering wheel once everything is in place. Testing the new switch after installation is key to make sure it’s working as expected.

Lastly, if the horn is dirty or damaged, you may need to clean or replace it. Cleaning the horn can often solve the problem if dirt or debris has accumulated inside. Use compressed air or a wire brush to clean the horn thoroughly. If cleaning doesn’t restore its function, the horn itself might be broken, and in that case, replacing it will be necessary. When replacing the horn, install the new one in the same spot where the old one was, ensuring a secure fit and proper connection.

Preventative Maintenance for Your Horn Attachment

| Maintenance Tip | Description | Frequency | Tools Needed | Benefits |

| Regularly Check the Fuse | Fuses can blow unexpectedly, so it’s worth checking them regularly to ensure they are in good condition. | Every 3-6 months | Fuse tester or multimeter | Prevents sudden horn failure and ensures safety on the road. |

| Keep the Wiring Clean and Dry | Moisture and dirt can cause corrosion in the wiring. Ensure everything is clean and dry to avoid electrical issues. | After heavy rains or when cleaning the car | Clean cloth, air compressor or brush | Avoids electrical issues caused by corrosion or moisture, maintaining the integrity of the system. |

| Use Quality Parts | When replacing components, always use high-quality parts that are designed for your specific vehicle to ensure longevity and performance. | Each time you replace a part | OEM parts or high-quality replacements | Enhances the performance and lifespan of your horn and ensures it works as expected. |

When to Seek Professional Help

- You Can’t Identify the Issue: If you’ve gone through the troubleshooting steps and still can’t pinpoint the problem, it’s time to consult a professional. They have the experience and tools to diagnose the issue quickly.

- You’re Not Comfortable Working with Electrical Components: Horns are connected to your vehicle’s electrical system, which can be tricky and risky to handle without proper knowledge. If you’re not experienced with electrical systems, it’s safer to leave the work to a professional.

- The Problem Is Beyond Basic Repair: If the horn issue is related to more complex parts of your vehicle, such as the steering wheel assembly or the car’s electrical wiring, a professional mechanic can handle these complicated repairs more efficiently.

- Persistent Horn Problems: If your horn continues to malfunction after replacing parts like the fuse, wiring, or switch, a mechanic can further investigate any underlying issues that may not be immediately apparent.

- Time-Sensitive Situations: If your horn isn’t working and you rely on it for safety, getting a professional mechanic to fix it promptly can ensure you’re not putting yourself at risk on the road.

- Lack of Proper Tools: If you don’t have access to specialized tools, such as a multimeter for checking wiring or a wrench to remove the horn, a professional will have the right equipment to get the job done effectively and efficiently.

Understanding the Importance of Proper Horn Attachment Functionality

A properly functioning horn attachment is essential for the safety of both the driver and others on the road. Your vehicle’s horn serves as a crucial communication tool, allowing you to alert other drivers to potential hazards or to make your presence known in an emergency. Without a reliable horn, you risk facing dangerous situations where you can’t react promptly to avoid accidents. Whether it’s a blown fuse or loose wiring, each issue with the horn’s attachment can compromise your ability to signal effectively.

The horn attachment connects to your vehicle’s electrical system, which is why even a small malfunction can lead to complete horn failure. In some cases, faulty wiring or a damaged switch can prevent the horn from sounding altogether, leaving you without the means to alert others in critical situations. While minor issues might not seem urgent, ignoring them can lead to bigger, more costly repairs down the road.

Regular maintenance of your horn attachment ensures that all components remain in optimal condition. This not only helps in avoiding unexpected breakdowns but also prolongs the lifespan of the horn system. Cleaning the horn and keeping the wiring dry can prevent the buildup of rust and corrosion, which are common culprits of horn malfunctions. Additionally, using high-quality parts for replacements ensures the overall performance and longevity of the system.

It’s also important to address issues with the horn attachment immediately when you notice them. Whether it’s a weak sound, strange noises, or complete failure, prompt action can save you both time and money. Regular checks and preventative maintenance can keep your horn working as it should, ensuring you’re always prepared to alert others when needed. If you’re unsure about the cause of the issue, seeking professional help ensures that your vehicle’s horn is repaired quickly and correctly.